CHANGING A WHEEL

Vehicles equipped with a jack and wheelbrace

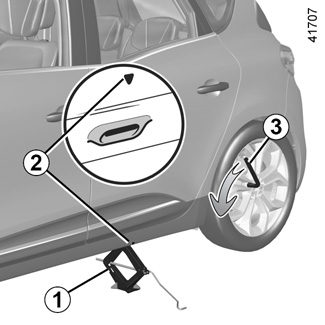

If necessary, remove the wheel trim.

Use the wheelbrace 3 to slacken off the wheel bolts. Position it so as to be able to push from above.

Offer up the jack 1 horizontally; the jack head must be lined up with the sill, closest to the wheel concerned, as shown by arrow 2.

Start cranking the jack up by hand to align the base plate (which should be pushed slightly under the vehicle).

Turn the wheelbrace until the wheel lifts off the ground.

Undo the bolts and take off the wheel.

Fit the emergency spare wheel onto the hub and rotate it until the mounting holes in the wheel coincide with those of the hub.

Tighten the bolts, checking that the wheel is correctly positioned on its hub and unscrew the jack.

With the wheel on the ground, tighten the bolts fully and have the tightness of the bolts checked and the emergency spare wheel pressure checked as soon as possible.

Switch on the hazard warning lights.

Keep the vehicle away from traffic and on a level surface where it will not slip.

Apply the parking brake and engage a gear (first or reverse, or P for automatic transmissions).

Ask all the passengers to leave the vehicle and keep them away from traffic.

If the vehicle is parked on the hard shoulder, you must warn other road users of your vehicle’s presence with a warning triangle or with other devices as per the legislation applying to the country you are in.

When the emergency spare wheel is located underneath the vehicle, it is vital to take the emergency spare wheel out before lifting the vehicle.

Risk of injury.

Anti-theft bolt

If you use anti-theft bolts, fit these nearest the valve (wheel embellisher may not be able to fit).

If you have a puncture, replace the wheel as soon as possible.

A tyre which has been punctured should always be inspected (and repaired, where possible) by a specialist.